The shoes make the man. Nothing says style and class better than exotic skins. However, not all exotic skins are suitable for making men's shoes.

The shoes make the man. Nothing says style and class better than exotic skins. However, not all exotic skins are suitable for making men's shoes.

Characteristics of a Suitable Exotic Skin

- Size of the Skin. Men's leather shoes come in different sizes to cater to the diverse market. The size of the shoe primarily determines the amount of leather required for the task. The size of the skin must be reasonable to prevent wastefulness or non-completion of the shoemaking project. Also, the size of the scales should be proportionate to the size of the product.

- Durability. The skin of choice for men's leather shoes should be highly resistant to wear and tear. Scuffs and blemishes make the surface of the shoes look less attractive which means designers must consider the conditions in which the intended user will be wearing the shoes. Exotic shoes are likely to cost you a pretty penny, so it only makes sense to want more use out of them.

- Smoothness. Fashion-forward men prefer footwear with smooth leather. Such shoes are stylish and easy to maintain. Rough shoes, on the other hand, require a good scrub during clean-up. They may also need special treatment for them to look presentable.

- Flexibility. A good pair of shoes should be flexible. However strong the leather is, it should allow the wearer to walk comfortably. Additionally, the upper portion should not crease easily to preserve the elegant look of the shoes.

- Size of Scales. Scaled hides are some of the most distinguished exotic skins for making men's leather shoes. Ideally, it is easier to work with skins with smaller scales than larger ones and they look more proportionate on a shoe.

- Blending. With a fancy upper of the shoe, it is necessary to blend it with matching components to maintain high standards. These often overlooked factors play a significant part in the shoe's overall feel.

These are the top five hides and skins which meet the considerations for making men's leather shoes.

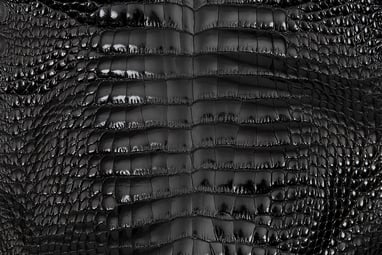

1: Alligator Belly

Second and third-grade gator skin is one of the best raw materials for making stylish footwear, but at a cost. The skin is flexible, soft, and durable. It is advisable to purchase the alligator skin in pairs for uniformity. You can use the tail skin to make a belt matching the shoes.

2: Crocodile Flank

The crocodile side skin is a common substitute for the alligator skin due to its lower cost. For consistent contours, manufacturers prefer to buy the left and the right flanks of the same croc for a pair of shoes. The flanks have a uniform circular scale shape which makes a pair of shoes look more cohesive than varying scale sizes.

3: Shell Cordovan

Shell cordovan leather has a natural characteristic gloss, and it is scratch-resistant. There is a treatment for removing scuffs restoring the original look of the shoe. Note this

4: Caiman Skin

Some caiman skin dealers sell the whole skin instead of the flanks or the belly. Since the back hide of the caiman is extremely hard and rigid, manufacturers typically prefer the belly skin for shoes (although the hornbacks are commonly used for cowboy boots).

5: Lizard Skin

Lizard skin has small scales which create a regular pattern, making it prime material for making classy men's leather shoes. Due to its relatively low cost in the world of exotics, the skin integrates elegance and affordability in a high-end footwear.

Don't Forget About Your Soles

The outsole of any shoe significantly determines the durability of a pair of shoes and the comfort it provides to the wearer. Two common options for high-end shoe soles are:

- Leather soles. Most high-profile men's leather shoes feature leather soles. Their sleekness exhibits a professional look and they are a perfect match for exotic leather shoes. However, not all types of leather are suitable for outsoles. For instance, leather from the underbelly of an animal is tender, and it would not last if used to make the soles.

- Rubber soles. Rubber strikes a balance between durability and cost-effectiveness. Moreover, rubber offers a perfect grip. Seasoned manufacturers make rubber soles for men's leather shoes so meticulously that they provide the elegance of leather soles.

The Foot Structure

Foot anatomy is critical in designing ergonomic shoes. When wearing shoes, the weight of the body spreads over the foot pads and the soles. The footprint is not even, and the heel carries more weight than the front of the foot. Therefore, there are some design considerations a footwear manufacturer has to make such as:

- Foot pads. For maximum comfort, the foot pads must assume the shape of the foot. Such a design helps even weight distribution without straining the blood vessels and the nerves. Poorly made pads can result in severe inflammation of the feet.

- Sharp-Pointed Designs. The footwear industry ranks pointed shoes among the most appealing shoes. Such shoes misalign the toes making the foot to assume an abnormal shape. This kind of footwear can lead to severe foot disorders such as ingrown nails, corns, and hammer toes.

Just because as a designer you have the best skins at your disposal, does not mean you have to forsake comfort for aesthetics.