Ever since they hit the scene in various forms, sneakers have not only been fashionable in-demand footwear, they have also become a status symbol; a statement. Also earning its stripes as a status symbol in the high-end footwear market is ostrich skin. With its distinct pattern and feel on the skin, ostrich leather has become a globally sought after material to satisfy the financially well-off sneakerheads’ needs.

Why Ostrich Skin?

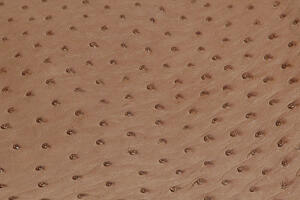

Exotic skins have shaken up the high-fashion leather market, with ostrich skin being one of the most sought after skins. Ostrich leather is uniquely indented. The markings on the skin, called quills, produce a stunning piece of finished leatherwork, whether in sneakers or other leather accessories.

It is one of the supplest skins in the exotic skin market. When used to make sneakers, ostrich leather provides a one-of-a-kind gentle interior. Coupled with a full-quill exterior, sneakers made from ostrich skin turn heads.

Skin Selection

A well-crafted ostrich leather sneaker is the product of a rigorous skin selection process and great artistry. Getting the right skin, to the seasoned shoemaker, is an easy task. However, for the less decorated shoemaker, these pointers should help:

Grading

Ostrich skin is categorized into grades. To understand grading, you must understand cuts. The skin is marked into quadrants. The occurrence of defects in the quadrants determines the grade. If the skin does not have any visible defects, it is a Grade I skin. If it has defects in one quadrant, it is a Grade II. If it had defects in all quadrants, the skin is a Grade IV skin. Grade II thru IV feature prominently in many a shoemaker’s workshops.

Cutting the Skin

Ostrich leather is a handful. A mature ostrich skin will yield about 16 square feet of plush skin. From 16 square feet, you can get about four pairs of sneakers. When cutting the skin, you need to pay attention to the defective areas. You could cut around them, or you could match two defective parts for parity during production.

Getting clean cuts shouldn’t be hard, mainly because standard weight ostrich leather is between 0.8 to 1.4 millimeters thick. This thickness makes the skin easy to work with. The cuts will also determine if you make a full quill, semi-quill or smooth skin pair of sneakers. Typically, two-thirds of the skin will be full quill while the rest is either partial or smooth skin. If you're looking to dazzle, a full quill pair of sneakers is sure to turn heads. However, to make the most out of the skin, you can use both the full quill and smooth skin for a stunning pair. Just make sure you put the same quill pattern on the same parts of each shoe so the pair matches.

Storage and Care

Ostrich skinis sensitive to elements such as heat and humidity. After you have completed the sneaker, you should store it in a dark place, preferably in a box or wrapped in absorbent paper. Use silica gel packs in storage boxes to absorb any moisture that might damage your exquisite footwear. Additionally, avoid lumping the sneakers together. Instead, put them in boxes and stack the boxes on top of each other, so the tough sole doesn’t scuff the leather.

The exotic skin sneaker market continues to gather momentum and command high price tags, thanks to the uniqueness of such skins such as the African ostrich skin. For the fashionista who values style and functionality, ostrich leather sneakers are a must-have.