Alligator skin, as a leather to make apparel and goods, has been used since the early 1800s in saddles, shoes, boots, and more. Even then it was recognized for its balance of workability and durability, but in the 1900s, when tanning was standardized as part of the process, it was lauded for the softness we love it for even today.

Exotic leathers, like alligator skin, aren’t like other leathers. From harvesting and tanning to buying and caring for it, alligator skin requires some special considerations and additional knowledge. It’s important to understand how alligator skin is ethically sourced and how the buying process differs from other leathers – from sizing and pricing to dyes and more.

Quick Links

- Alligator Information

- Sustainable Alligator Skin Harvesting

- Alligator Tanning

- Grading Alligator Skin

- Sizing Alligator Skin

- Buying Alligator Skin

- Alligator Skin Pricing

- Caring for Alligator Skin

Alligator Information

Alligators are native only to the Southeastern United States and China. For the purposes of alligator skin, the leather traditionally comes from the American Alligator. While in the same family as crocodiles, Florida is the only place in the world where both crocodiles and alligators coexist. Still, there are significant differences in their habitats, appearance, temperament, and skin.

The native habitats have a significant impact on their skin. Because crocodiles have to fend off vicious predators, their skin is a bit thicker, which is why alligator skin is easier to work with. Similarly, the scale pattern is visibly different. Whereas alligator scales are larger in the middle and grow smaller towards the outside, crocodile skin is more symmetrical, with rectangular scales. The varied scale pattern on alligator skin adds to its character.

Another important consideration is population. Because alligators are limited to only two native habitats, their population is significantly smaller than that of crocodiles. For example, it’s estimated that 1.25 million alligators live in Florida. While they were once considered endangered and at risk, conservation efforts and attention to harvesting and farming alligators have enabled the species to remain stable. The wider range of habitats for crocodiles makes them more plentiful, but conservation efforts are still in place to protect the species.

Sustainable Alligator Skin Harvesting

In the 1960s and 1970s, there were considerable, and justifiable, concerns regarding the survival of the American alligator species. In response, research organizations and government agencies began to form and work together to identify and address the detrimental harvest practices and establish an ethical framework for harvesting alligator skin.

Prior to these protections, there were significant detrimental practices, including overharvesting. Further, there was a failure to sex select when harvesting, which resulted in declines in the female alligator population. This was exacerbated by a year round open season, which led to significant declines in population as hunting during nesting season not only caused a decline in female alligators but also impacted future generations.

Today, there are multiple organizations including the Convention on International Trade in Endangered Species of Wild Fauna and Flora (CITES) and The International Union for Conservation of Nature (IUCN) that help establish sustainable practices for the conservation of animals, especially those in the exotic skin and animal trading industries.

Further, Pan American Leathers has long valued ensuring conservation and animal welfare aspects of the leather industry. While there are, certainly, larger conversations to be had about how animals are treated, ethically sourced animal skins can actually work towards animal welfare and conservation.

To be proactive about our role in these trades and efforts, we established our own rating system to ensure that our own supply chain is ethically sourced and provides for both sustainability and conservation of exotic animals and reptiles. We factor in biodiversity, animal welfare, conservation, and use of meat, scoring all of our providers on their harvesting strategies and do not work with any provider who scores a 0 on any of those criteria.

Alligator Farming Efforts Increase Alligator Population

Alligator Farming Efforts Increase Alligator Population

In an effort to restore the animal and the industry, researchers at Rockefeller Refuge in Louisiana developed a revolutionary program of alligator farming/ranching that removes eggs from the wild, incubates and hatches them, and then, two years later, returns between 14% and 17% of those hatchlings to the wild. Upon return, they are between three and six feet in length, healthy, and capable of defending themselves in the marsh.

As a result, the percentage of returns (e.g., 14%) is greater than the survival rate for eggs left in the marsh. In 1972, the alligator season was opened only in Cameron Parish and lasted 13 days. Other parishes were gradually added until the season became statewide in 1981. Louisiana’s wild and farm alligator harvests currently exceed 300,000 animals annually, while the population level (based on aerial nest surveys) remains stable.

Due to the success of this sustainable use program, the alligator was removed from the endangered species list in 1987. This program also set an example that inspired similar sweeping changes in the crocodile locales across the globe. So much so that by 1996, one-third of all crocodile species were sufficiently abundant to support well-regulated annual harvests, and one-third of the species were no longer in danger of extinction but are not harvested. No other group of vertebrate animals has undergone such a dramatic improvement in its conservation status.

Alligator Tanning

Once alligator skin is harvested, it must undergo a tanning process to turn the raw skin into usable and workable alligator skin leather. Without the tanning process, the skin is highly susceptible to decomposition and bacteria. For that reason, caring for alligator skin prior to working with it is essential and that means a multi-step tanning process.

Tanning Process Overview

Tanning Process Overview

First, the skin is dry salted to help preserve the skin. From there, it’s moved to the beamhouse where several steps are taken to prepare the skin for tanning.

Beamhouse operations include:

- Soaking to skin clean the skins

- Liming to descale the skin and create a smooth finish

- Deliming to raise the acidity

After the beamhouse, the skin is then pickled to remove any remaining bone matter. The first step of the tanning process is then possible.

Chrome tanning converts the material into inorganic material, which is then shaved to degrease and thin out the leather. It’s then re-tanned to re-soften the leather for working and dried either by hang-drying or toggling.

The skin is then dry cleaned and can be colored as needed. The final step is to, once again, shave the leather to remove any remaining impurities. Finally, the alligator skin is ready for the finishing touches.

A Detailed Look at the Tanning Process

When we receive the alligator skin from the suppliers, they’re stiff and extremely susceptible to the elements. They arrive already salted, which removes the water from the skins and preserves them until we can work them.

Our first step is soaking the skins in water to clean them, removing the salt, and rehydrating the skin so we can begin working them.

The Tanning Process Itself

The next stage in the tanning process is liming. This is essential as it removes scales, nails, mucins, and natural greases and fats. It also splits the fibers and makes the collagen in the skin workable. The skin must then be delimed to rebalance the acidity.

The next phase is the pickling, which involves an acid bath that helps break down the bones and calcium in the alligator skin so it is more pliable. After the pickling process comes the chrome bath, which makes the alligator skin durable and no longer susceptible to the elements.

Once this is done, it is no longer organic skin; it has become inorganic leather.

Then, we re-tan the alligator skin, this time using vegetable-based products. This is done so the tougher skin from the initial tanning process is supple again. We then either hang-dry or “toggle” (which uses a special type of oven to evaporate the water) to remove the water and humidity.

The alligator leather is then ready to dye. After that, we shave it down to the required thickness and weight for the application, and finish it with seasons and protective coats so it feels good, looks good, and is protected from the elements.

From there, it goes onto the manufacturer where they turn it into the garments, footwear, furniture, handbags, etc. you’re familiar with.

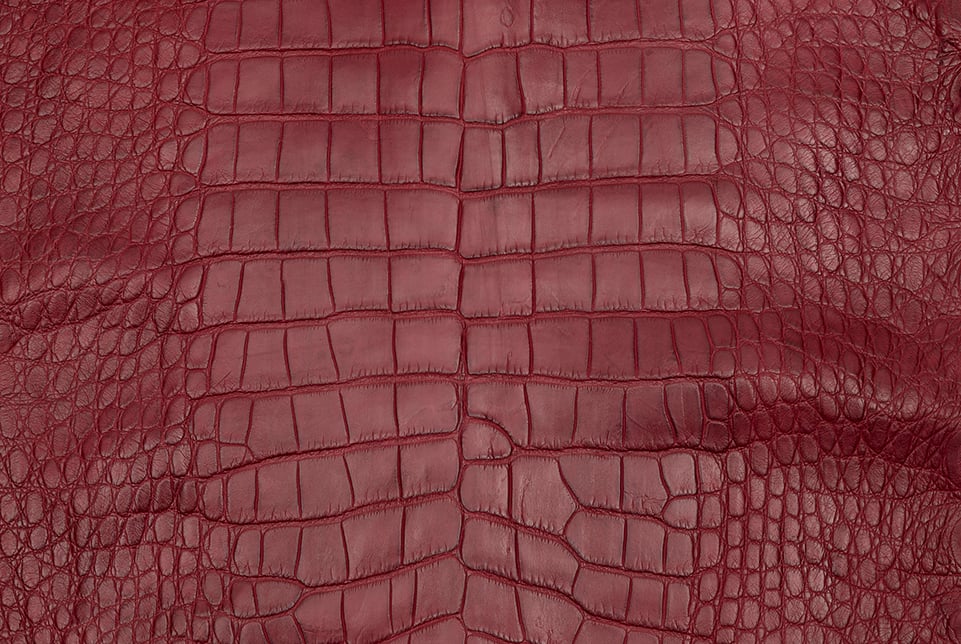

Grading Alligator Skin

There’s a reason alligator skin is used in so many consumer goods. As mentioned above, alligator skin has a non-uniform pattern that gives it character. It’s soft, supple, and stylish. And, when dyed, there’s even more appeal. Whether you’re an aficionado of alligator skin or a designer or manufacturer looking for a supply, you may just be learning about alligator skin.

It’s important to note, when buying alligator skin, that not all skin is the same. While alligator leather shares similar properties, much like diamonds or other natural commodities, there are variances that require attention. In fact, when purchasing alligator skin you’ll want to pay close attention to both the grade and size.

What Are The Grading Standards?

What Are The Grading Standards?

PanAm Leathers grades alligator skin on the midsection only, including the belly and flank. The condition of the head and tail are not considered in the grading. The grades are defined as follows:

- Grade 1: No defects in the belly

- Grade 2: One cluster of defects on the outer edge of belly or flank

- Grade 3: One cluster of defects in the center belly

- Grade 4: Clusters of defects in two different quadrants of the midsection

- Grade 5: Worse than grade 4

Defects are most often scars, scratches, shading or scaling deformities. In some rare cases, defects may include holes and grain issues. Anything with holes or grain issues would be downgraded to a grade 4 at best. Skins that are grade 3 or better will not have holes or grain issues in the midsection.

- Grade I/II alligator skin usually makes watch bands, handbags, upholstery and luggage.

- Grade II/III alligator skin is usually used in sneakers, boots, shoes, garments and wallets.

- Grade III/IV alligator skin tends to be used for belts, and small accessories where manufacturers can cut small panels around the defects

Sizing Alligator Skin

Next to grading, sizing is also important to the buying process. Alligator skin is measured in centimeter width at the widest point of the belly. Depending on the width of the skin, you’ll be able to make different goods using the various grades of the alligator skin.

For example, the 20-29 cm range is typically used to make watch straps, shoes, and smaller goods. From 30-34 cm, we can get small handbags, boots, and larger wallets. From 35-39cm, small garments, medium-sized handbags, and other medium-size accessories like tablet cases are options.

From 40-49 and 50-59 cm, you move into larger garments, handbags, motorcycle accessories, and belts. Alligator skin larger than 60 cm is most commonly used for luggage and larger upholstery.

Understanding what you hope to create will impact the size of the skin you purchase, so knowing your goals before going into the buying process is essential.

Buying Alligator Skin

With a good understanding of grading and sizing, you’re ready to start looking! While Pan American Leathers is a leading seller of alligator skin, you might wonder what other options exist. We’re not the only suppliers of alligator skin. The alligator leather supply landscape is varied, and there are multiple options for you.

Alligator Skin Distributors

Alligator Skin Distributors

Distributors buy skins from tanneries, warehouse them, and distribute them to buyers. They keep a large stock on hand, which is convenient for a buyer in a time crunch. However, for them to make money, they typically mark it up and charge you higher prices.

Also, their selection is often limited. If you’re looking for a specific alligator skin, you may be out of luck — or you’ll need to go with an alligator skin you didn’t really want. Even if the distributor can source what you want, it’ll typically be at a premium price with long deliveries and may not come out exactly as you want.

In contrast, when you buy directly from a leather company like Pan American Leathers, you cut out the middleman, eliminating the distributor mark up and allowing yourself the product flexibility and direct communication you need.

Leather Tanneries

We’re not the only tannery in the market for alligator skin. However, we are one of the only remaining independent alligator skin tanneries worldwide – meaning we are not owned by one of the major fashion houses. Being owned by a fashion house creates a huge conflict of interest for these tanneries as they market their alligator skin to brands outside of their corporate family.

As a result of these complicated relationships, these tanneries typically charge very high prices and may gain valuable insight into their competition — you! In contrast, we have no conflict of interest.

Further, most tanneries are outside of the U.S. Because alligator skin is classified as a wildlife product, it’s subject to both U.S. Customs and the Fish and Wildlife review, which can take time. As a result, deliveries from foreign alligator skin tanneries commonly take several months.

On the other hand, the Pan American Leather team tans and finishes our skins right here in the United States. We can ship domestically with less delay while still fully complying with all U.S. Fish and Wildlife requirements, including full documentation and proper tagging. That means faster deliveries without cutting corners.

And, if you’ve got questions about your order, about the leather, or about exotic animal skins in general, communication is easy with fewer time zone complications and no language barrier. In addition, we can provide customized and tailored service based on your needs. For example, we can work with customers in person to develop product lines and make product adjustments in a matter of days.

Manufacturers

Your manufacturer will sometimes offer to source alligator skin for you. This is a good option because they know exactly what they need to make your products. Just make sure they don’t overbuy. The cutting process is important, and any manufacturer should be diligent about that step. You don’t want to end up paying for more skin than you need.

Competition in the exotic leathers and alligator skin market has been a positive force in our industry for some time. It’s required a lot of suppliers to raise the bar on their standards and service. Still, as a buyer, one of your best shopping assets is knowledge about the process and product.

Alligator Skin Pricing

You know what to look for, you know where to buy, but now the big question, “What’s that cost?” It’s important to know that cost will first depend where the skin is coming from. As noted above, buying alligator skin or alligator leather from a U.S. based company will be cheaper simply because the “product” is here. There’s no transportation or import costs.

However, there are additional factors, including grade as well as supply and demand, that impact the cost of alligator leather as well as other exotics.

Grading Factors

This factor is pretty straightforward and logical. The most expensive alligator leather includes the large grade I skins. The least expensive are the smaller pieces with a lower grade. In short, the better grade and larger the piece, expect to spend more.

Supply and Demand Factors

Day to Day Factors

In normal market conditions, the most influential supply and demand variables affecting the price of alligator skin are grade and size.

The 40-60 cm skins with the fewest defects are the most sought after for handbags, garments, etc. However, they are the hardest to come by because large alligator skin comes from the wild. The larger the skin, the older the animal and, thus, it’s more likely to have defects. The alligator in its longer life in the wild has, simply, endured more and so the skin may include defects such as scars, scratches, bites from fighting, feasting, and general wear.

Large alligator skins are, therefore, rarely in pristine condition. The few that are command top dollar in the marketplace.

Environmental Conditions

Like any other game, alligators are subject to environmental conditions and disasters. For instance, when Hurricane Katrina ripped through Louisiana in 2005, it destroyed the alligators’ habitat causing dramatic effects on their population from eggs to feeding patterns. Naturally, this affects the supply of alligator skin not only from the wild – but also from the farms.

Farmers collect alligator eggs from the wild (approximately 14% of the alligators are returned to the wild at a certain age to conserve their population). This means the disaster that immediately and harshly affected the wild population also affects the farms a few years later.

However, Hurricane Katrina is a dramatic example. More normal shifts in annual weather patterns can also affect the availability of alligators. In fact, prices for wild alligator skin typically reset every year after the wild season.

Cost Factors

Naturally, a tannery will charge more for an alligator skin that costs more to produce. For example, basic finishes like matte and glazed are typically the least expensive. On the other hand, specialty finishes that require more work, expensive chemicals, or additional materials command a higher price.

For example, shaving a skin to a thin, garment weight requires more time than shaving it to a heavier weight, say for handbags. Alligator skin with pearlized finishes requires chemicals that are very expensive versus the materials required to finish a matte skin. Other finishes, like metallic or iridescent, will have similar markups.

Similarly, if you want a light color like yellow, pink or white, there’s typically a small surcharge attached to them, as it involves more work.These types of costs are passed through to the customer, but they are relatively small compared to the other factors affecting price.

Further, there are only a handful of tanneries worldwide that can make certain specialized products. If you really want a special product, expect to pay a premium price because it may not be available elsewhere.

Similarly, the cost of alligator skin that needs to be made to order will depend upon the number of skins ordered per product. A lot of the work that goes into producing alligator skin is set up, like mixing chemicals or dyes, setting water temperatures, etc. Whether the tannery makes one alligator skin or 100 skins, the set up time is about the same. As a result, tanneries will typically apply substantial surcharges for smaller orders.

Caring for Alligator Skin

Caring for Alligator Skin

Given the amount of time, effort,and money that goes into preparing alligator skin for consumer goods and products, understanding how to care for your alligator skin items is crucial, and it’s important information to be passing on to your customers. You want them to enjoy and appreciate the product for as long as possible and that means properly caring for your alligator leather.

First and foremost, these are general care tips as alligator leathers with specialized finishes may require additional or different care. Storage is certainly an important aspect of this care. However, cleaning and conditioning your alligator skin products will increase their longevity while maintaining their beauty.

Storage

This is, obviously, one of the most important factors for care. Treat animal leathers like other precious materials. Avoid the following environmental conditions:

- Direct sunlight

- High humidity or moisture

- Excessive heat

If, for some reason, the item gets wet, dry it immediately with a soft cloth. If needed, it can be hung to dry.

Similarly, alligator items with soft sides may need to be stuffed with newspaper or other items to retain their shape. This is particularly true of alligator skin handbags. Also, avoid stacking or storing alligator skin items near items that may scratch or damage the surface.

Cleaning

Though alligator skin was originally designed to withstand water, it is very important to avoid water and harsh cleaning chemicals. Both water and chemicals can damage the surface. Instead, try a dry towel first. If you must clean for caked in dirt or dirt in crevices, a damp towel can be used, but then dry the area thoroughly.

Conditioning

Like your own skin when it’s exposed to harsh elements, alligator skin should be conditioned to prevent cracking, fading, or peeling. You’ll want to be sure to use a conditioner that’s made specifically for the exotic leather you’re conditioning. The wrong conditioner can discolor or damage the surface of your product.

For that reason, it’s always best to test your conditioner on a small, non-noticeable area of the product first.

The better care you take of your alligator skin leather, the longer life it will have and the longer it will maintain the qualities that led you to this purchase from the start. Many people love alligator skin leather because of its distinctive appearance from the shine to the supple and soft texture, so keeping those characteristics intact requires appropriate care.

Pan American Leathers prides itself on its variety of alligator skin leathers and contract tanning for alligator skins. If you’re looking to learn more, check out more of our blog, and if you’re in the market for alligator leather, contact us and let’s talk!